The AMT gearbox, which has been rejected for a long time, is back. This time it makes us sit up and take notice?

The importance of gearbox for a car is self-evident, and an excellent gearbox may contribute the most to the driving performance of the car. In today’s automobile market, there are also many types of gearboxes, such as manual gearboxes (MT), automatic gearboxes (AT), double clutch gearboxes (DCT), continuously variable gearboxes (CVT) and so on.

(Shift lever of AMT gearbox)

In recent years, in the gearbox lineup of civil vehicles, it seems that the semi-automatic gearbox (AMT) has been expelled from the team, and it seems that it has disappeared. Now the latest news is that it is back, but it has "practiced a martial arts."

Advantages and disadvantages are equally distinct.

The research and development of semi-automatic AMT gearbox began in 1960s. Eaton, Daimler Benz and Scania were pioneers in developing AMT gearbox. The so-called AMT transmission is based on the ordinary manual transmission, which mainly changes the shift control part of the mechanical transmission, that is, by adding an automatic control system controlled by TCU under the condition of unchanged overall transmission structure, the shift automation is realized. Therefore, AMT is actually a robot system to complete two actions: clutch operation and gear selection. You can understand it this way: AMT is essentially a manual gearbox, just a computer to help us shift gears.

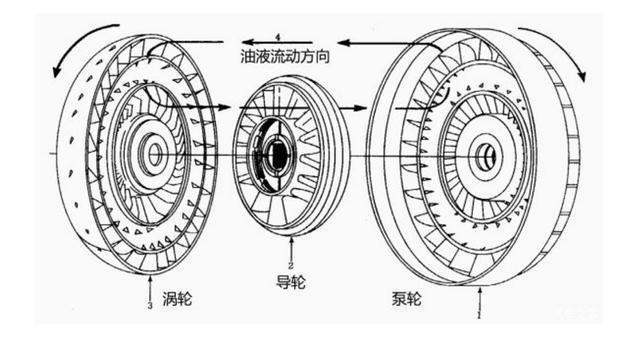

(AMT gearbox does not need hydraulic torque converter)

The biggest advantage of AMT gearbox lies in its cost. Compared with the traditional AT automatic gearbox, AMT has no torque converter and surrounding components, and its internal structure will be much simpler. It is for this reason that we used to see it in entry-level cars.

(The driving performance of AMT gearbox is very general)

The advantages are over, and now it’s the disadvantages. Perhaps you should have guessed that the shift quality of AMT gearbox is very general by using manual gearbox to realize automatic shift. Especially when shifting gears 1-2 and 2-3, you can feel obvious frustration every time, because computers are never as smart as people’s right feet. If it is a manual shift, we will be more cautious about the throttle when shifting gears, while AMT gearbox will "rudely" disconnect the throttle when engaging the clutch, and when the clutch is released, it will give the throttle command at once, which is how the sense of frustration comes from.

At the same time, because there is no hydraulic torque converter, the starting response of AMT gearbox is very anxious. Because considering the service life, the computer will not use semi-linkage for a long time, it will only do semi-linkage 2 seconds after you release the brake. Moreover, this force is quite small, and a small slope will cause the car to slip back.

(SAIC clearly marked MG3 with a driving reminder)

I used to drive a MG3 car with AMT semi-automatic gearbox for a long time. My solution to the above two problems is to look at the timing of the gearbox upshift and take the initiative to loosen the throttle to make the shift smooth; At the same time, when starting on a ramp, step on the brake pedal with your left foot, lightly oil the right foot and release the left foot again. Only in this way can we basically avoid these two serious injuries. If you think about it carefully, the purpose of AMT is to reduce the difficulty of driving, but if you adopt this operation, it will increase the learning cost.

Later, due to the lower cost of the dual clutch gearbox, the dual clutch with more perfect experience gradually replaced the position of AMT. Now, there are basically no new cars with AMT semi-automatic gearbox.

ZF let it change?

In order to meet the needs of the market, AMT is also making changes. Recently, ZF officially announced that it has developed an electric semi-automatic gearbox (eAMT) for front-drive hybrid vehicles. This gearbox is a product that integrates the company’s electric drive system (eVD) and semi-automatic gearbox (AMT) into one system.

(ZF eAMT prototype)

ZF brought a prototype car, which also made us understand the working principle of eAMT system more clearly. On the test vehicle equipped with the system, eAMT is installed at the rear axle, and forms the vehicle power system with the front power unit. Because eAMT has its own electric drive unit, it is no longer affected by the interruption of engine traction, and can continuously output power and improve the acceleration ability of the whole vehicle. In addition, eAMT can also output power at the same time as the front power unit, so that the vehicle can realize the electric four-wheel drive mode. In this way, it is equivalent to a low-cost electric four-wheel drive system solution.

I have to admit, as a transmission giant, ZF has a really good understanding of transmission. The core problem of using AMT gearbox in fuel vehicle is the matching with internal combustion engine, which is difficult to do well because of its physical characteristics. The essence of eAMT is a P4 hybrid solution with two reduction ratios, and AMT and engine are completely decoupled. Coupled with the superior controllability of the motor, the calibration difficulty is much lower than that of AMT of pure diesel locomotive.

In this era when new energy vehicles are popular, the matching of power system is no longer based on a single gearbox. EAMT not only achieved good results, but also greatly reduced the cost. This is the greatest value of this system.

Xiaobian language

The advantages and disadvantages of AMT gearbox are very clear. We should make use of its advantages and avoid those disadvantages. eAMT system does this. If this system can be implemented, we can say that AMT semi-automatic gearbox has finally found its own value.